3PE Coating Pipe, 3PE Anticorrosive Pipe

Introduction

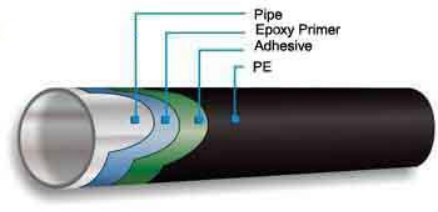

3PE coating pipe is short for “three layers structure polyethylene anticorrosion coating steel pipe”. There are three layers in this pipe coating structure,

The first one: Epoxy layer (Thickness > 100um)

The second one: Adhesive layer (Thickness: 170um~250um)

The third one: Polyethylene layer (Thickness: 1.8~3.7mm)

What kind of pipes could be coated with 3PE or FBE?

Coating standard:

ANSI/AWWA C104/A21.4 American National Standard for Cement-Mortar Lining for Ductile-Iron Pipe and Fittings for Water

ISO 21809 Petroleum and natural gas industries -- External coatings for buried or submerged pipelines used in pipeline transportation systems

DIN 30670 Polyethylen coatings of steel pipes and fittings

Size:

Outer Diamter: 219.1mm - 4064mm (8" - 160")

Wall Thickness: 3.2 mm - 40mm

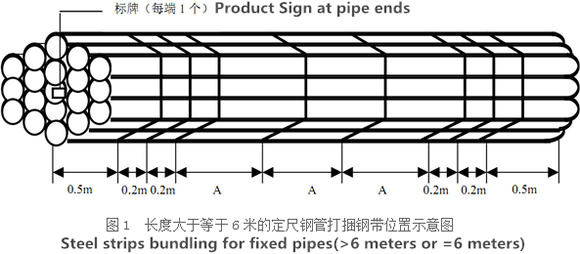

Length: 6mtr-18mtr

End

Square ends (straight cut, saw cut, and torch cut).

Beveled for welding, beveled

Surface

Lightly oiled

Hot dip galvanized

Electro galvanized

Black

Bare

Varnish coating

Anti rust oil, Protective Coatings

(Coal Tar Epoxy, Fusion Bond Epoxy, 3-layers PE)

Usage

Due to the characteristic and advantage of the 3PE coated pipe, it is widely used in many kinds of applications such as oil & gas, water transmission, heat transmission, mining, fire-fighting, thermal power station, electric power, communication facilities, highway, chemical pharmaceutical, printing and dyeing and agricultural applications. And with its further development, the 3PE coated pipe will play more and more important role in the global development.

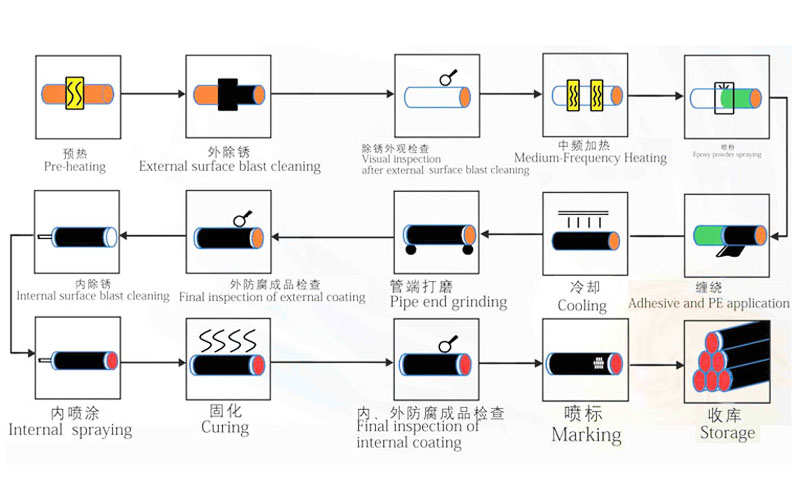

Manufacturing Process

Contact: Mr. Rao

Phone: +86-153 0846 7103

Tel: +86 731 8504-7708

Email: info@jinxi-steel.com

Add: No. 568,Chuanggu Industrial Park, Queyuan Road, Tianxin District, Changsha City, Hunan Province, P.R.China.

Whasapp