ERW Steel Pipe, ERW Casing, ERW Carbon Steel Pipe, MS ERW Pipe, GI ERW Pipe, Stainless ERW Pipe

Sizes:

OD (Out Diameter): 21.3-660mm

WT (Wall Thickness): 1.0-20mm or sch5, sch10, sch40, sch80, st, xs

Standard:

For ERW Pipe

ASTM A53 Gr.B, ASTM A178, ASTM A252

API 5L X42/46/52/56/60/70

ASTM A500, ASTM A513

EN 10204/10217 S235JR,S275JR, S355,S355JR,S355J2H

For EFW Pipe

Carbon steel EFW pipe: ASTM A671,ASTM A672

Alloy steel efw pipe: ASTM A691

Coating

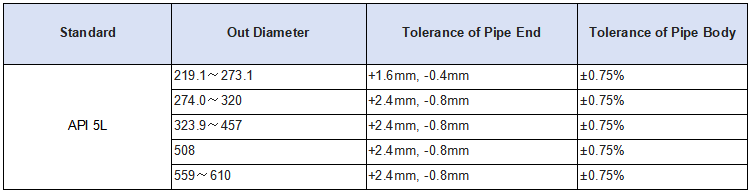

Tolerance of Outside Diameter

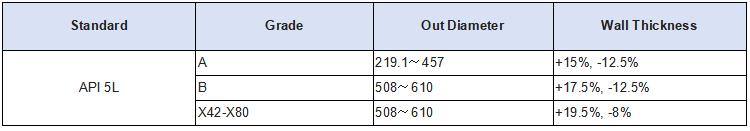

Tolerance of Wall Thickness

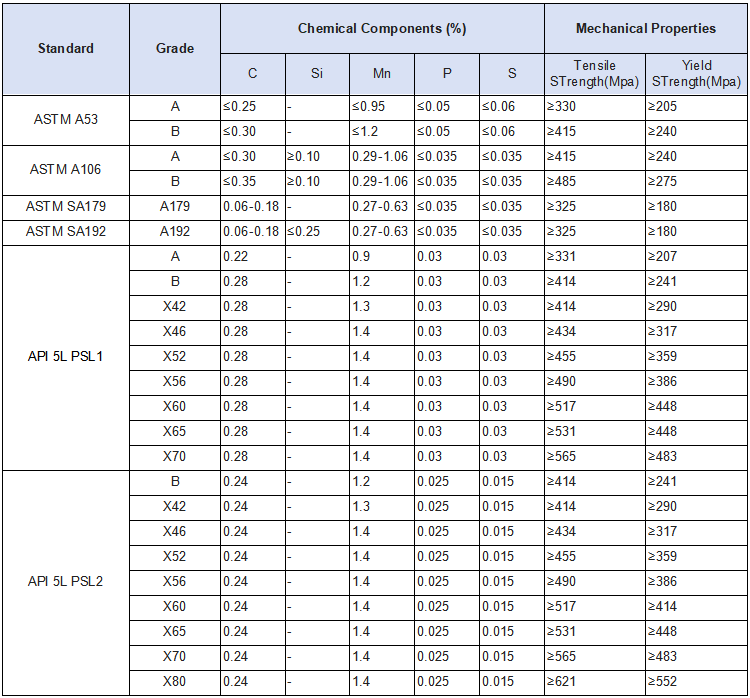

Chemical Analysis & Mechanical Properties

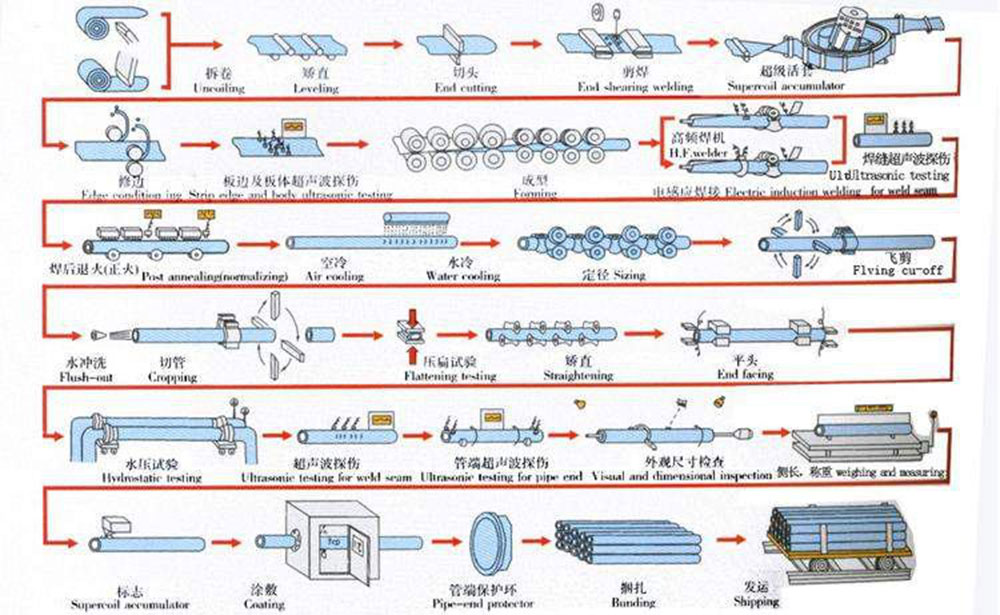

Manufacturing Process

High-frequency straight seam electric-resistance welded steel pipe(erw steel pipe) is hot-rolled coil after forming machine, the use of high-frequency current skin effect and proximity effects, the tube edge heating and melting, squeeze roller under pressure welding to achieve production.

High-frequency resistance welding steel pipe, welding pipe and ordinary welding process is not the same, the weld is made of the base metal melt from the body, the mechanical strength is better than the general pipe. Smooth appearance, high precision, low cost weld high and small, favorable 3PE anti-corrosion coating. There are significant differences in the welding methods between high frequency welded pipe and submerged arc welded pipe. As the welding is done instantly at high speed, the difficulty of ensuring the quality of welding is much higher than that of submerged arc welding.

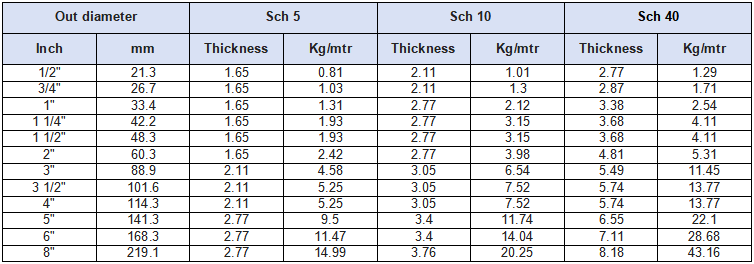

Out diameter: 1/2" -24"

Thickness: sch5, sch10, sch40, sch80, st, xs (according to the ASME B36.10M)

Small Diameter ERW Pipe Specification

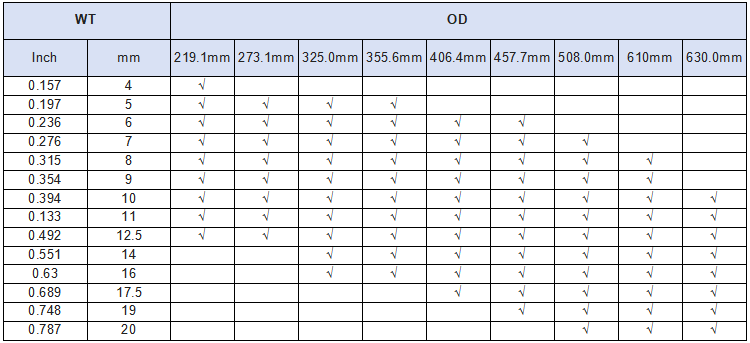

Large Diameter ERW Pipe Specification

Contact: Mr. Rao

Phone: +86-153 0846 7103

Tel: +86 731 8504-7708

Email: info@jinxi-steel.com

Add: No. 568,Chuanggu Industrial Park, Queyuan Road, Tianxin District, Changsha City, Hunan Province, P.R.China.

Whasapp