Seamless Steel Pipe & Tube, Carbon Seamless Steel Pipe, SMLS Pipe & Tube, CS Seamless Pipe Black Seamless Pipe, GI Seamless Pipe

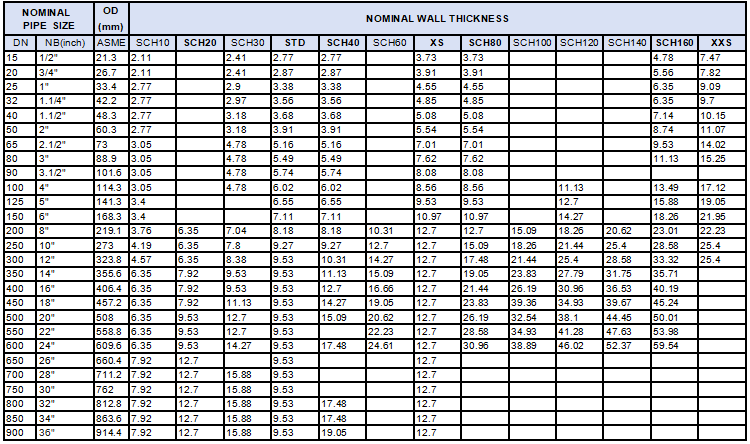

Sizes:

Maximum diameter: 36" (914.4mm) minimum diameter: 1/2" (21.3mm)

Maximum thickness: 60mm mininmum thickness: 2.11mm

SCH: SCH10,SCH20,STD,SCH40,SCH60,XS,SCH80,SCH100,SCH120,SCH160,XXS

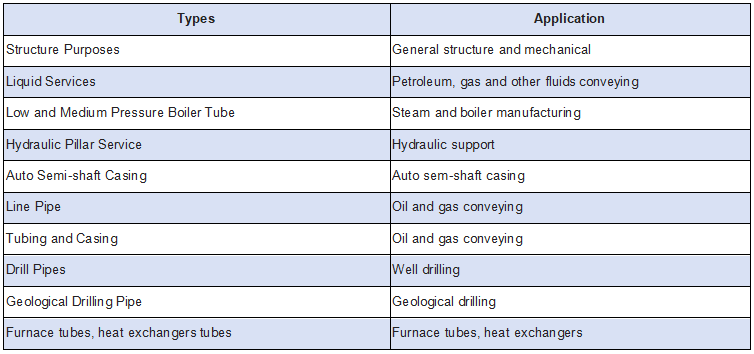

Uses:

1.Chilled water pipe

2.Steam/condensate pipe Heat exchanger pipe

2.Marine/offshore pipe

3.Dredging pipe

4.Industrial pipe

5.Oil and gas pipe

6.Fire fighting pipe

7.Construction/structure pipe

8.Irrigation pipe

9.Drain/sewage pipe

10.Boiler tube

Coating

Standard

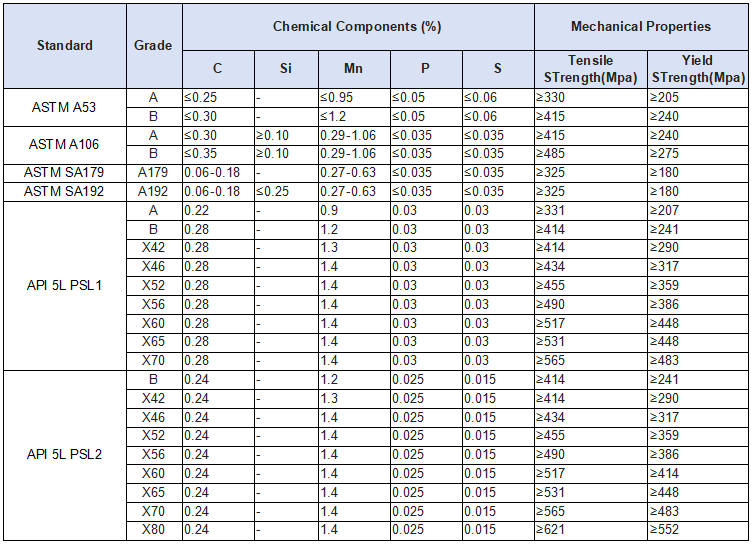

Chemical Components & Mechanical Properties

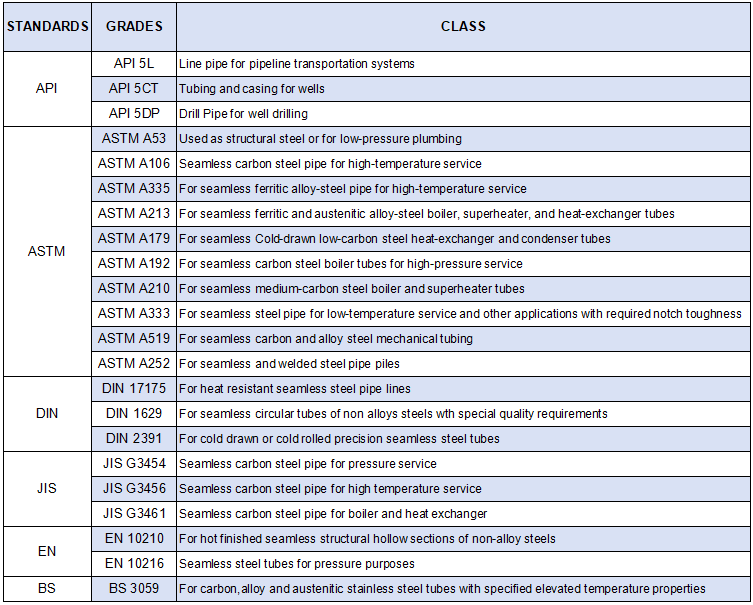

Classification

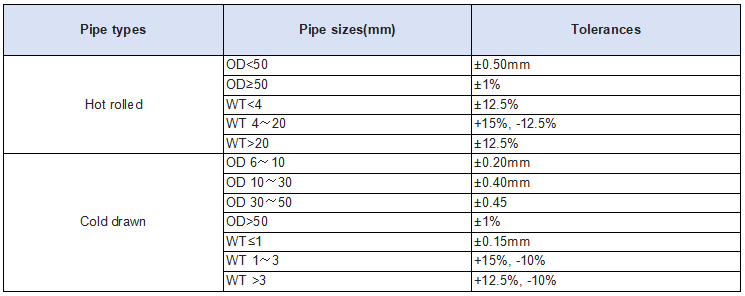

Tolerances

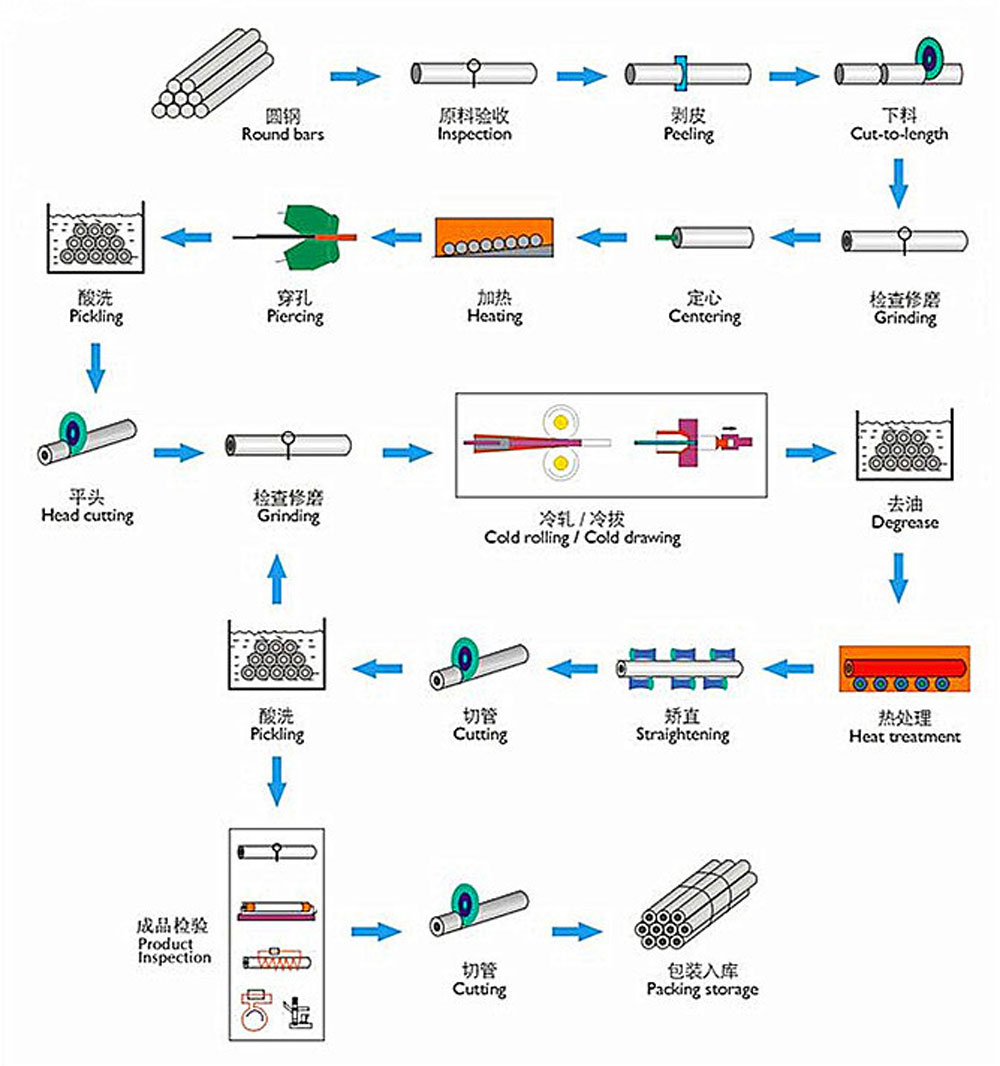

Manufacturing Process

The process begins with solid steel rounds, or billets, being cut to a specified length and sent through a walking-beam reheat furnace, where temperatures reach nearly 2,300°F. After exiting the reheat furnace, the preheated rounds are turned into a tube shell in the rotary piercing mill as the billets are cross-rolled between two barrel-shaped rolls at a high speed.

The seamless shells enter mandrel mill, where they are rolled over a retained mandrel to provide the needed OD size and wall thickness for the next process. The process is carefully monitored using a state-of-the-art hot-wall measuring system. The shells are then reheated for final forming in a 24-stand stretch-reducing mill, where outside diameters are formed to customers’ exacting specifications. Wall thickness is again verified using a hot-wall measuring system. After being rotated and advanced on the walking-beam cooling bed, the pipes are batch cut and transferred to an in-process storage area, where they are handled by computer-controlled gantry cranes.

Maximum diameter: 36" (914.4mm) minimum diameter: 1/4" (13.7mm)

Maximum thickness: 60mm mininmum thickness: 2.11mm

Contact: Mr. Rao

Phone: +86-153 0846 7103

Tel: +86 731 8504-7708

Email: info@jinxi-steel.com

Add: No. 568,Chuanggu Industrial Park, Queyuan Road, Tianxin District, Changsha City, Hunan Province, P.R.China.

Whasapp